Services

Top Services

Advanced Technologies

Company

Top Services

Advanced Technologies

Home

Logistics Technology Solutions

Inventory Management Solution

Gain inventory control, optimize your supply chain, and drive sustainable growth.

OVERVIEW

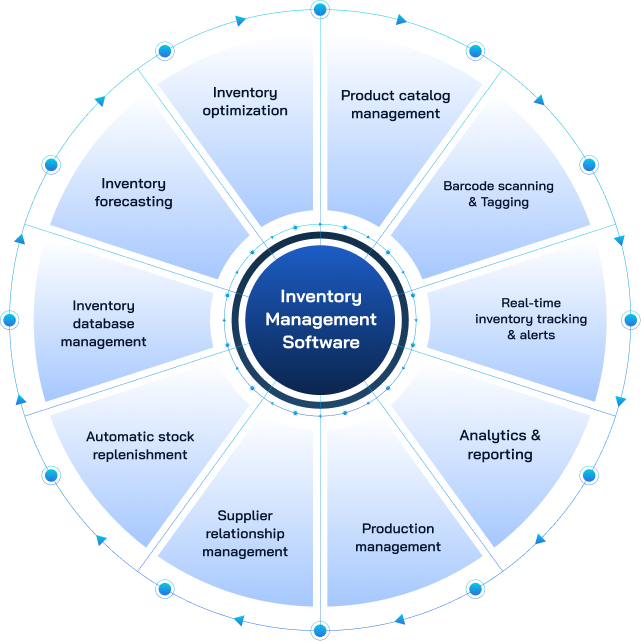

Inventory management software delivers real-time visibility, automates stock processes, and provides actionable insights that help your business optimize inventory control and reduce costs. We develop inventory solutions tailored to retailers, manufacturers, healthcare facilities, and distributors with robust features to efficiently manage, plan, and track inventory throughout the entire supply chain, from procurement to fulfillment.

INVENTORY SOLUTIONS

When your operations involve complex workflows, strict compliance standards, or massive SKU volumes, generic inventory systems fall short. We build custom inventory management software from scratch, architected around how you actually work, with flexible data models that adapt as you grow. End-to-end development covers intuitive interfaces for warehouse staff and admins, plus web and mobile apps that put inventory control in everyone's hands, wherever they are.

Real-time visibility into stock levels, locations, and movement across all sites. Barcode or RFID scanning, automated receiving, and fulfillment workflows that keep pace with demand. No more guessing what's in stock or where it went.

We build warehouse management systems tailored to your exact operational needs. From picking and packing automation to shipping management and slot planning, our team implements the precise features your warehouse requires, guiding you from initial concept through full deployment.

Data management tools process the massive volume of warehouse information: inventory counts, transactions, operations, and performance metrics, turning raw data into actionable insights, helping businesses spot inefficiencies, optimize processes, and make strategic decisions grounded in what's actually happening on the warehouse floor.

We build forecasting tools that analyze historical sales, market trends, seasonal patterns, and external factors to predict future demand accurately, helping you stock what sells and avoid what doesn't.

We build logistics stocking software tailored to your exact distribution needs. From inventory positioning across distribution centers to automated stock transfers, replenishment planning, and cross-docking management, our team implements the precise features your logistics network requires, guiding you from initial concept through full deployment.

We integrate IoT technology to create connected inventory ecosystems with automated data capture, real time item tracking, and environmental monitoring for temperature-sensitive goods like pharmaceuticals and perishables.

FEATURES

AI INTERGRATION

Optimize pricing to boost revenue and inventory turnover.

Monitor equipment to prevent downtime and ensure smooth operations.

Track inventory across locations with automated reordering.

Data-driven demand forecasting and inventory optimization.

Real-time insights adjust stock and replenishment to cut costs and ensure availability.

BENEFITS

Track inventory across all storage locations from one system, ensuring orders pull from the right warehouse and customers receive accurate shipment updates without manual coordination.

Real-time visibility into all products eliminates warehouse trips to check availability. Know what's in stock instantly when demand spikes or customer inquiries come in.

Built-in analytics identify trends, forecast demand, and measure performance, enabling proactive inventory decisions based on patterns and opportunities, not reactive scrambling.

Accurate inventory tracking prevents lost sales from stockouts and eliminates manual counting errors. Meet delivery timelines consistently while giving customers real-time tracking, not vague estimates.

Track actual stock levels and reorder precisely when needed, avoiding both costly stockouts and expensive overstocking that ties up capital and leads to product waste.

INTERGRATIONS

ERP integration syncs inventory across departments, providing real-time visibility into stock, orders, and movement so finance, operations, logistics, and planning work with accurate data.

CRM integration syncs sales and supply chain data, automates orders and invoices, and speeds fulfillment without manual errors.

EDI integration automates documents with suppliers and logistics partners, cutting manual work, reducing errors, and speeding transactions.

We integrate inventory with scanners, RFID, and mobile devices for automated tracking, faster processing, and fewer errors.

ADVANCED TECHNOLOGY ADOPTION

AI inventory tools analyze orders, sales history, and stock levels to forecast demand and improve inventory management.

Blockchain enhances asset tracking, improves traceability, increases transparency, and reduces supply chain costs.

Big data uncovers hidden patterns, optimizes reorder points, and reduces stockouts and excess inventory.

FAQ

Inventory management systems serve diverse industries with specific stock needs. Retail operations use IMS for accurate product tracking and order management. Healthcare facilities ensure critical medicines and supplies stay in stock. Warehouses and distribution centers streamline shipping, receiving, and storage. Any business managing physical goods benefits from IMS optimization of inventory control and operational efficiency.

Absolutely. Our IMS plugs directly into your fleet management software so everything runs from one platform. Vehicle inventory, parts, supplies, delivery schedules, and route optimization all sync automatically. No duplicate data entry, no switching between systems, just complete visibility and control over fleet operations and inventory from a single dashboard.

We build inventory systems around how your business actually operates, not force you into generic workflows. Every feature addresses your specific operational challenges, integrates with your existing processes and technology stack, and connects seamlessly with supply chain platforms, analytics tools, manufacturing software, and other systems you already use. You get a solution tailored to your needs, not a compromise.

RESOURCE HUB